Specialised Management and Leadership Services

-

home

-

Services Home

-

our people

-

baseline review

-

proven methodology

-

key definitions

-

The Human Condition

-

implementation

-

international expertise

-

services

-

philosophy

-

contact

Key definitions

Safety

Safety is the state of being in which people are conscious of, successfully manage, and feel accountable for the potential for injury or loss.

Consciousness and accountability are fundamental at all levels for safety.

“Good” quality

“Good” quality is a predictable degree of uniformity and dependability at low overall cost, suited to the customer.

(Using the definition based on the work of W. Edwards Deming.)

The definition applies to end-users and within organisations to internal customers. Work quality includes safety.

Customer satisfaction depends on service and value. In turn service depends on quality and timeliness while value depends on quality and cost. Thus, quality is part of both value and service. Quality of work is essential internally and in the market.

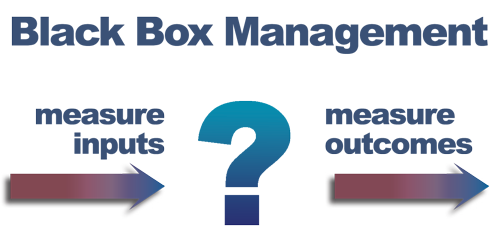

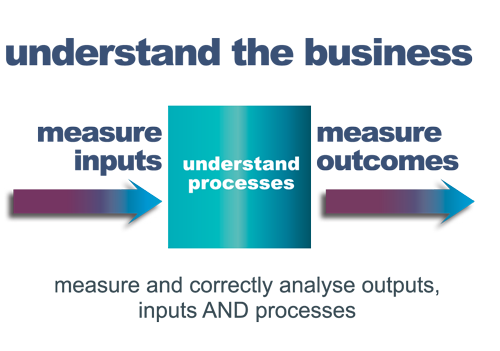

Process-based approach

Process-based approach is based on improving the efficiency and quality of key processes rather than the typical conventional approach of arbitrarily trying to change outcomes or improve operation of individual departmental silos.

Secondly, fiddling with inputs can worsen outcomes and raise costs due to inefficiencies from process tampering.

Improving processes though always improves results.

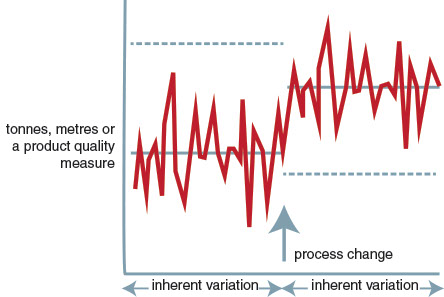

It's vital to understand two separate concepts—process stability (extent and type of variation) and process capability (the ability to meet quality, specifications and volume targets).

Seven-step methodology:

1. Structure accountabilities to align with processes;

2. Eliminate special causes of variation to stabilise and control processes;

3. Reduce inherent variation to tighten control over productivity components;

4. Improve and lift productivity components;

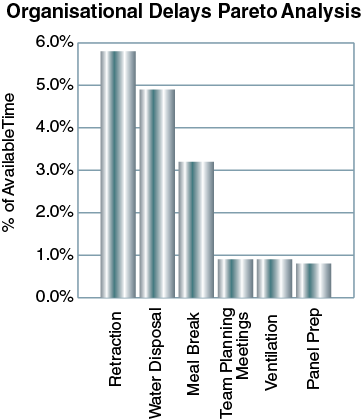

5. Remove out-of-process impediments;

6. True continuous improvement with locks to sustain improvements;

7. Invest in new technology or resources raising capacity or cutting costs.

Note that investments in new capital and additional resources are a last resort. After the first six steps such investments may not be needed.

Statistical Process Control

Statistical Process Control is use of data in simple, statistically sound ways to understand a process to keep it under control and make it behave the way we want it to behave.

One of two keys to successfully increasing productivity is an organisation's ability to control and improve processes and products. The other key is involving people to improve their work processes. SPC meets both needs.

Key graphs for graphical analysis and reporting:

Run charts

Pareto charts

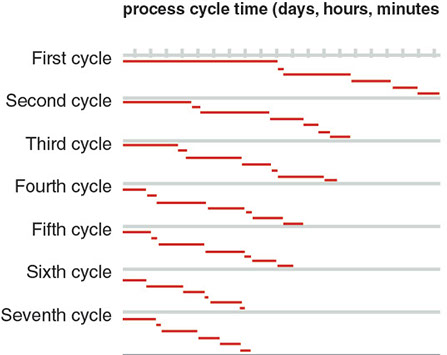

Cycle Time charts

Cycle time run charts

Cycle time charts are presented as run charts

Run charts as SPC control charts

Collectively they are known as Statistical Process Control although that term is sometimes strictly limited to use of control charts.

SPC gives people control over their own work in ways that align practical understanding and meet universal human needs and business / process needs. SPC is essential for optimal teamwork and accountability.

“Measure and reward the things you value and the behaviours you want”

System

A system is a group of actions or elements providing a definite method, procedure or guide. Systems can be tangible or intangible. They can be defined in writing or implicitly accepted and followed as organisational habits or practices. They can be deliberately designed, or more commonly they develop haphazardly and unconsciously over many years under influence of many different people.

In practical terms, a system is simply anything that drives ways of doing things.

Systems are ingrained at every level in every organisation. Systems can be so deeply entrenched people are not even aware they're grinding away within a system. Many executives and managers don't see the direct connection between systems and unproductive or ineffective (or unsafe) behaviours. Instead they focus on individual people's attitudes.

An example of a system is the procedure and format used to measure and report business performance. Measuring performance is by far the most powerful system for driving behaviours because it displays achievement or lack of achievement. This focuses people and directs and energises their action - behaviour.

Consider what happens in a business that only measures and emphasises volume alone. People often take shortcuts ignoring quality and costs to maximise volume. This can lead to poor quality and increase waste of resources resulting in high costs and dissatisfied customers.

Another system, although not as powerful, is the remuneration system. This drives behaviours and attitudes. A poorly designed salary and bonus system can drive short-term behaviour and prevent teamwork. This undermines customer satisfaction and future business. An effective salary and bonus system though will drive constructive behaviour aligned with the business' purpose, principles and goals.

An example of an undefined system is the giving of recognition. This focuses people and drives their behaviour. If an organisation preaches that teamwork is important yet gives formal and informal recognition mostly to individuals it drives individual behaviour that can undermine teamwork.

An example of an informal system overriding an organisation's intent is its values. Are customers really valued? When managers treat customers not just as an inconvenience but really seek to understand and serve customers, people throughout the business see service is valued. Values can be systems. They drive behaviour.

“We provide problem-solving tools. More importantly, we provide an organisation-wide problem-solving process”

“For business success and security build a competitive advantage – people armed with real understanding”